-

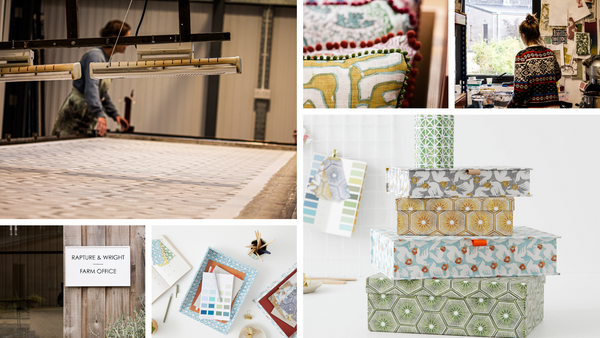

Transparent films are utilised to replicate the final design. One screen for each colour of the pattern is used to "etch" it onto the printing screens using these films.

-

The inks are blended to match your custom colour swatch or their standard colour chart.

-

The base fabric that has not been printed is rolled out and ironed onto the print table in the interim. To ensure that every part of the design lines up when they print, the pattern repeats on the print table are carefully calibrated.

-

As the first colour dries, the screen is cleaned and printed in that colour. The following colours go through the same procedure again. After being rolled, the fabric is cut to the desired length.

-

Although small-scale production requires a lot of time—two persons could need a day to print thirty metres of fabric—the outcomes are exquisite and one-of-a-kind.

View our Rapture and Wright Collection here.